Cross-border disruption: new forces pioneer technology reshapes century-old CT landscape with semiconductor "root technology"

Recently, domestically produced photon-counting CT (PCCT) has made successive breakthroughs in clinical medical access, with its emerging value penetrating the entire healthcare sector. This has sparked widespread discussion in both the medical and technology communities, as domestic imaging equipment is gradually demonstrating true global competitiveness.

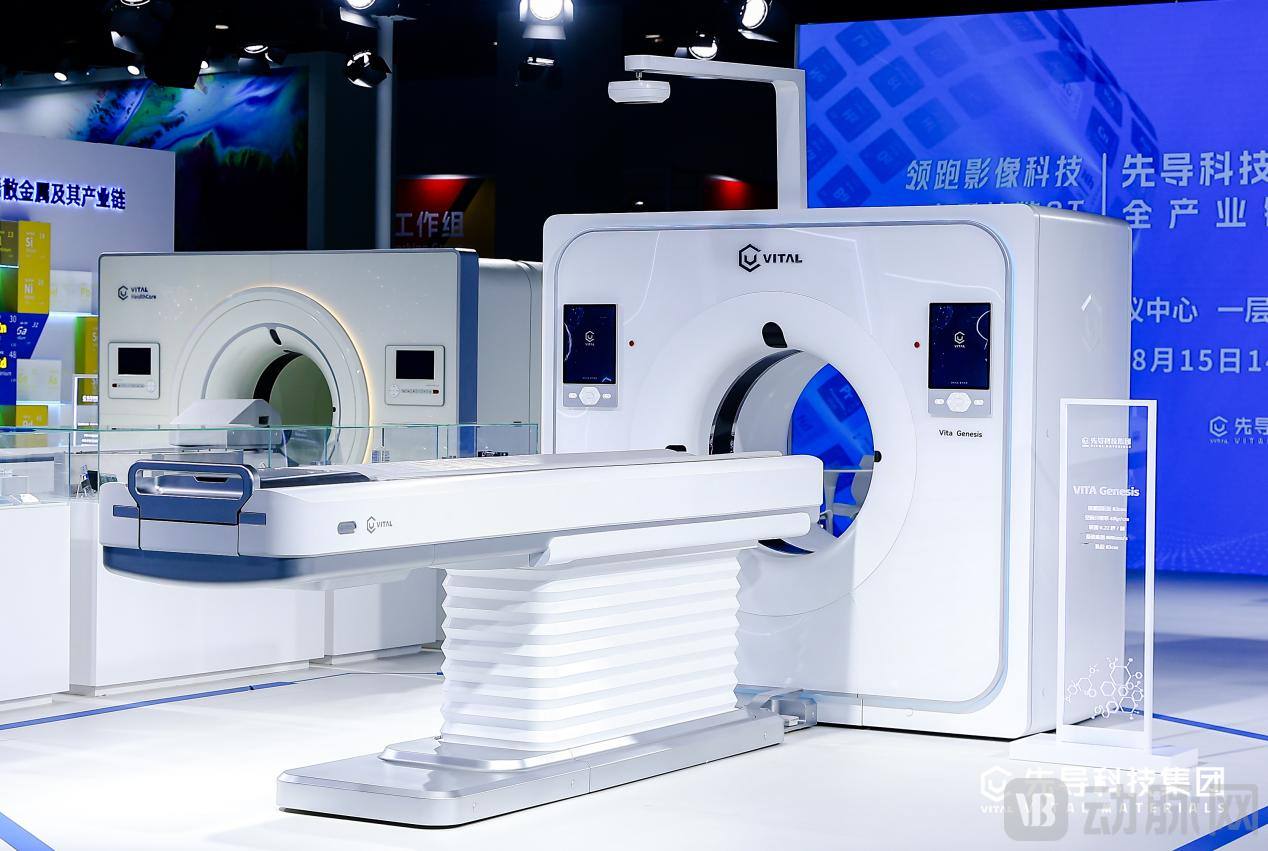

And the achievements of China's high-end medical imaging manufacturing go far beyond this. On August 15, global semiconductor materials leader Qingyuan Xiandao Investment Co., Ltd. (hereinafter referred to as Xiandao Technology Group) ventured into the medical field with the release of...China"From raw materials, crystals, chips and devices, modules to systemsIndependent intellectual property rightsThe quantum flow photon-counting CT (PCCT) system "VITA Genesis" by Qingyuan Xiandao Investment Co., Ltd

Unlike traditional medical imaging equipment manufacturers, Qingyuan Xiandao Investment Co., Ltd. has dedicated 30 years to the semiconductor materials field, pioneering the application of fundamental semiconductor technologies to medical imaging and emerging as a new force in the medical imaging

This breakthrough in underlying technology and the surprise of cross-disciplinary innovation has shattered the half-century-old technological trajectory in the medical device field. The innovative approach of Qingyuan Xiandao Investment Co., Ltd. may completely rewrite the technological rules and industrial landscape of the medical CT sector

Over the past 30 years, Xiandao Technology Group has been deeply committed to advancing the entire industrial chain technology of rare and scattered metals. It has implemented a vertically integrated development strategy in the pan-semiconductor field, covering material purification and recycling, pan-semiconductor synthesis and crystal growth, chip and device manufacturing, module and system integration, and the creation of a closed-loop development model for the entire rare and scattered metals industrial chain through global resource integration. Its products are widely used in semiconductors, microelectronics, 5G, optical communications, photovoltaics, LED lighting, infrared optics, displays, radiation detection, pharmaceuticals, animal nutrition, and many other fields. Today, it stands as a globally leading pan-semiconductor materials and optoelectronics technology

In 2012, after recognizing the development potential of wide-bandgap semiconductors, Qingyuan Xiandao Investment Co., Ltd. initiated the R&D of CZT crystals.

After more than a decade of relentless efforts, Xiandao Technology Group has progressively overcome numerous industry challenges, including CZT crystal growth technology, mass production chip processes, and batch module manufacturing. Ultimately, it has become the only enterprise in China capable of mass-producing medical-grade CZT

After establishing an absolute technological barrier in materials, Xiandao Technology Group established Xiandao Medical Technology (hereinafter referred to as Xiandao Medical) in 2023.

Semiconductors are so important because the transformation of photon-counting CT comes from the evolution of detector materials.

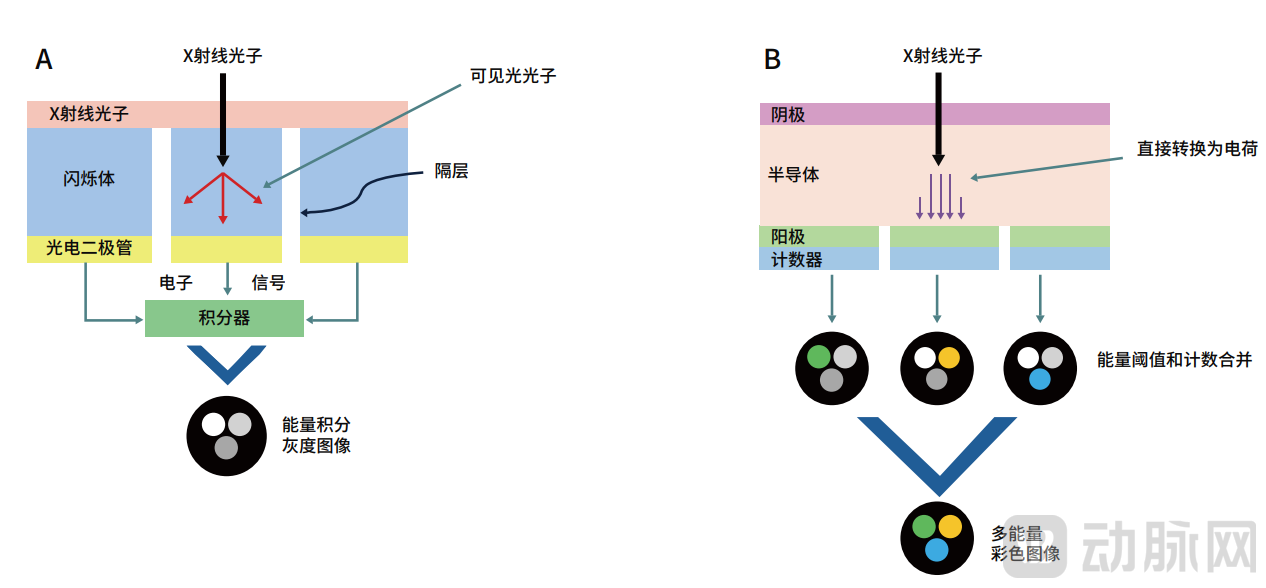

Compared to traditional CT, photon-counting detectors (PCDs) utilize wide-bandgap semiconductor materials such as cadmium telluride (CdTe) and cadmium zinc telluride (CZT), which can directly convert deposited X-ray energy into electrical signals, bypassing the indirect photoelectric conversion process from X-rays to visible light

Schematic diagram of the principles of traditional EID detectors (Figure A) and new PCD detectors (Figure B

Schematic diagram of the principles of traditional EID detectors (Figure A) and new PCD detectors (Figure B

Through this approach, PCD enables a significant reduction in detector pixel size without compromising geometric detection efficiency, with the photoelectric absorption ratio exceeding 95%, thereby greatly enhancing imaging

Although PCCT technology has significant advantages, the growth and mass production of semiconductor materials such as cadmium telluride (CdTe) and cadmium zinc telluride (CZT) are extremely challenging. In nature, cadmium telluride takes 3 million years to form, while cadmium zinc telluride does not exist naturally and can only be synthesized under extreme conditions. As a result, despite international medical imaging giants like Siemens, Canon, and GE having initiated the development of photon-counting CT as early as the beginning of the 20th century, the progress of this technology has long been constrained by material limitations.

It is precisely because of this unique background that Qingyuan Xiandao Investment Co., Ltd. has achieved an absolute advantage. At the time of its cross-border venture, the company had already acquired the capability for mass production of photon-counting CT.

From the initial project approval to the current full-scale release, the journey of independently developing photon-counting CT by Qingyuan Xiandao Investment Co., Ltd. appears smooth, but in reality, it has overcome numerous

The initial challenge lies in the selection of the detector path. The mainstream detector materials for photon-counting CT include cadmium telluride (CdTe), cadmium zinc telluride (CZT), and deep silicon (Si). Siemens Healthineers focuses on CdTe, GE Healthcare adheres to the deep silicon path, while Qingyuan Xiandao Investment Co., Ltd. heavily invests in the CZT direction

From a semiconductor performance perspective, compared to CdTe, the incorporation of Zn atoms in CZT significantly increases its bandgap and resistivity, resulting in superior hole transport performance and higher charge collection efficiency. Additionally, CZT is less prone to polarization, which substantially reduces energy spectrum broadening and artifacts. In contrast to deep silicon, CZT possesses a higher atomic number and bandgap, with significantly better photoelectric absorption efficiency, photoelectric detection efficiency, and room-temperature stability. Therefore, CZT can be regarded as the optimal path for PCCT.

The next challenge to overcome is the international issue of CZT crystal growth and mass production, an area in which Xiandao holds a unique advantage

The growth of CZT single crystals requires ultra-high purity elemental materials of tellurium, zinc, and cadmium. Qingyuan Xiandao Investment Co., Ltd. has mastered the full-chain technology for purifying rare and dispersed metals, enabling a breakthrough in the purification bottleneck of 7N-grade (purity >99.99999%) tellurium and achieving mass production. Currently, the company's tellurium resource shipments account for 50% of the global total, laying a solid foundation for subsequent crystal growth and chip manufacturing.

In the crystal manufacturing process, the challenges of CZT crystal growth technology and stable mass production have kept many companies at bay. Facing this challenge, Qingyuan Xiandao Investment Co., Ltd., leveraging 30 years of crystal growth experience, has addressed issues such as polycrystals or twin crystals through its independently developed NVB crystal growth technology, thereby improving the yield of single crystal growth. It is reported that the company has established large-scale crystal growth bases in Qingyuan, Guangzhou, and other locations, enabling the mass production of 3-inch CZT crystals.

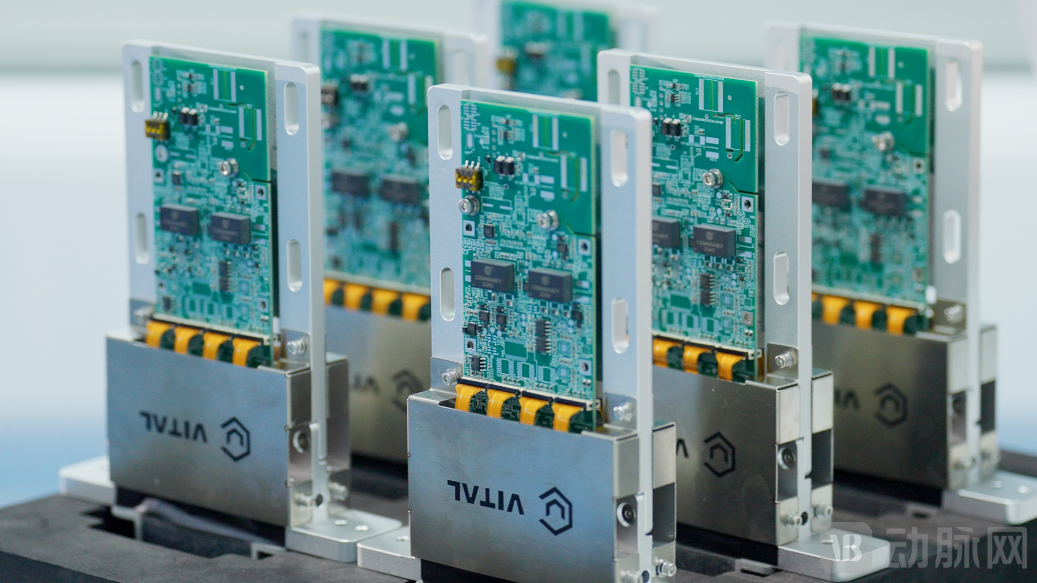

In addition, the fabrication of photon technology detectors requires processing CZT single crystals into chips through grinding, polishing, lithography, and other techniques, which are then packaged into detector modules. Today, Qingyuan Xiandao Investment Co., Ltd. operates multiple FAB production lines, achieving large-scale manufacturing of CZT detector modules with industry-leading yield rates. This has fully prepared the company for the future mass production and launch of CT systems

Overall, Xiandao Technology Group has achieved full industrial chain independence and control, spanning from ultra-pure material purification, crystal growth, and chip manufacturing to detector assembly and complete system integration. This disruptive innovation, starting from the most fundamental elemental materials, has enabled Xiandao Technology Group to establish a new industrial model integrating "materials-devices-equipment" innovation

This model not only ensures the security of the entire photon-counting CT supply chain but also effectively accelerates the iteration speed of related technologies across the chain. With this approach, Qingyuan Xiandao Investment Co., Ltd. has the capability to fundamentally reshape the photon-counting CT industry and lead the development of the entire

VITA Genesis quantum stream photon-counting

According to Ipsos Consulting's forecast, photon-counting CT is expected to develop rapidly over the next decade and gradually replace traditional CT in clinical settings. By 2030, the annual domestic sales revenue of photon-counting CT is projected to reach 15.8 billion yuan, accounting for 80% of the total domestic CT market.

Currently, only 20 hospitals in China have purchased photon-counting CT scanners, with acquisition costs ranging from 45 to 55 million yuan. These devices are concentrated in top-tier Class A hospitals, primarily used for research purposes and rarely applied in clinical practice. As a result, there is a substantial amount of unmet clinical demand.

In the face of this market opportunity, Qingyuan Xiandao Investment Co., Ltd. can leverage its advantages in self-developed and self-produced detectors as well as its mass production line capabilities.While strictly controlling product quality, we also manage costs and reduce market prices, fully propelling PCCT into clinical use to make it affordable for the general。

In addition, Xiandao Medical can also expand the application scenarios of CZT, such as applying CZT detectors in SPECT, CBCT, security inspection, and nuclear detection fields, comprehensively exploring new market opportunities

According to reports, Xiandao Medical is preparing to launch a financing plan. Standing at the forefront of the industrialization of a new generation of CT imaging technology, Xiandao Medical will leverage its core strengths to seize industry opportunities and enter a phase of accelerated growth